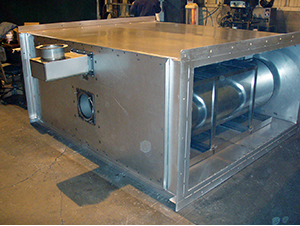

Custom Designed Gas IDF Heat Exchangers

Harbridge’s 30 year history in Engineering and Manufacturing high efficiency gas indirect heaters has given us the vast capability and experience to produce fully modeled heat exchangers to exacting standards. Our proprietary modelling program has been tested and proven in over 1500 applications worldwide. Whatever your specific situation, we are fully able to meet or exceed your expectations by considering a wide range of variables including specific duct sizes, fuel options, pressure considerations, elevation, burner sizes, output and efficiency concerns and many others.

We have several unique IDF heater designs available for a multitude of applications or outputs including heavy-duty crossflow tubular, counterflow tubular and high efficiency plate. All offer thermal efficiencies approaching 90% in a compact design with low pressure losses to reduce fan horsepower. All units are designed by our experienced Engineers in AUTOCAD with potential for 3-D modelling or design. Fully detailed lay-outs of your particular unit are supplied to our customers as part of the Engineering process.

Harbridge IDF heaters offer competitive outputs in typically 30% to 45% lower cube-space, and with 10% to 15% increase in efficiency to save YOU and your customer every day. We do not select or force-fit a pre-engineered unit from a catalog. Harbridge offers as much, or as little as, our customers’ design including options like fully functioning heater boxes, insulated duct sections, pre-piped and wired burner systems, condensate drains, thermocouple or pressure taps and others.

We have been proven and our units have been widely accepted in many industries including:

- Automotive

- Carbon fiber

- Food processing

- Battery Industry

- Air rotation & clean-room air supply

- Plastics

- Aerospace

Please download this literature for more information on our Gas IDF Heater Exchangers.