Slitter Scrap Collection System

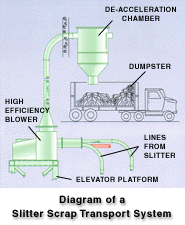

Harbridge’s Slitter Scrap Transport (SST) system was developed to automate the collection of 3-piece can slitter “hay”. It eliminates thousands of man-hours annually that would normally be needed to rake and collect waste at your sheet slitter or re-sizing operation by automatically collecting, chopping, and transporting slitter scrap to a common collection point. The SST system is a modular design, and expandable to allow several manufacturing lines into one collection point. It has been designed for nearly continuous service with only occasional off-line service or maintenance.

Typically, a three-piece can manufacturing operation would drop first and second operation slit scrap on the manufacturing floor as a waste product of production. This scrap is very loosely packed at minimal packing density; due to the low density, scrap must be removed often and by completely manual labor. Due to the low scrap density, more frequent trucks are also required from your scrap reclaimer to remove scrap from your plant, thus increasing labor and transportation costs.

Harbridge has eliminated this source of inefficiency and unnecessary expense with its SST system.

Please download this literature for more information on our Slitter Scrap Transport system.